DYWI® Drill Hollow Bar

DYWIDAG’s Hollow Bar Micropile system combines drilling, grouting, and reinforcement in one solution. Ideal for limited-access sites, unstable ground, and tight schedules. From preventing uplift to providing cost-effective foundations for transmission towers, our Hollow Bar Micropiles are engineered for speed, stability, and strength - even in the most complex geotechnical environments.

11 Related Downloads

DYWIDAG DYWI® Drill Hollow bar System - Approval Z-34.14-255 (Germany)

DYWIDAG DYWI® Drill Hollow bar System - Brochure (Germany)

Geotechnical product range - Brochure (Germany)

Geotechnical Equipment - Brochure (Germany)

Fast to install and high-performing

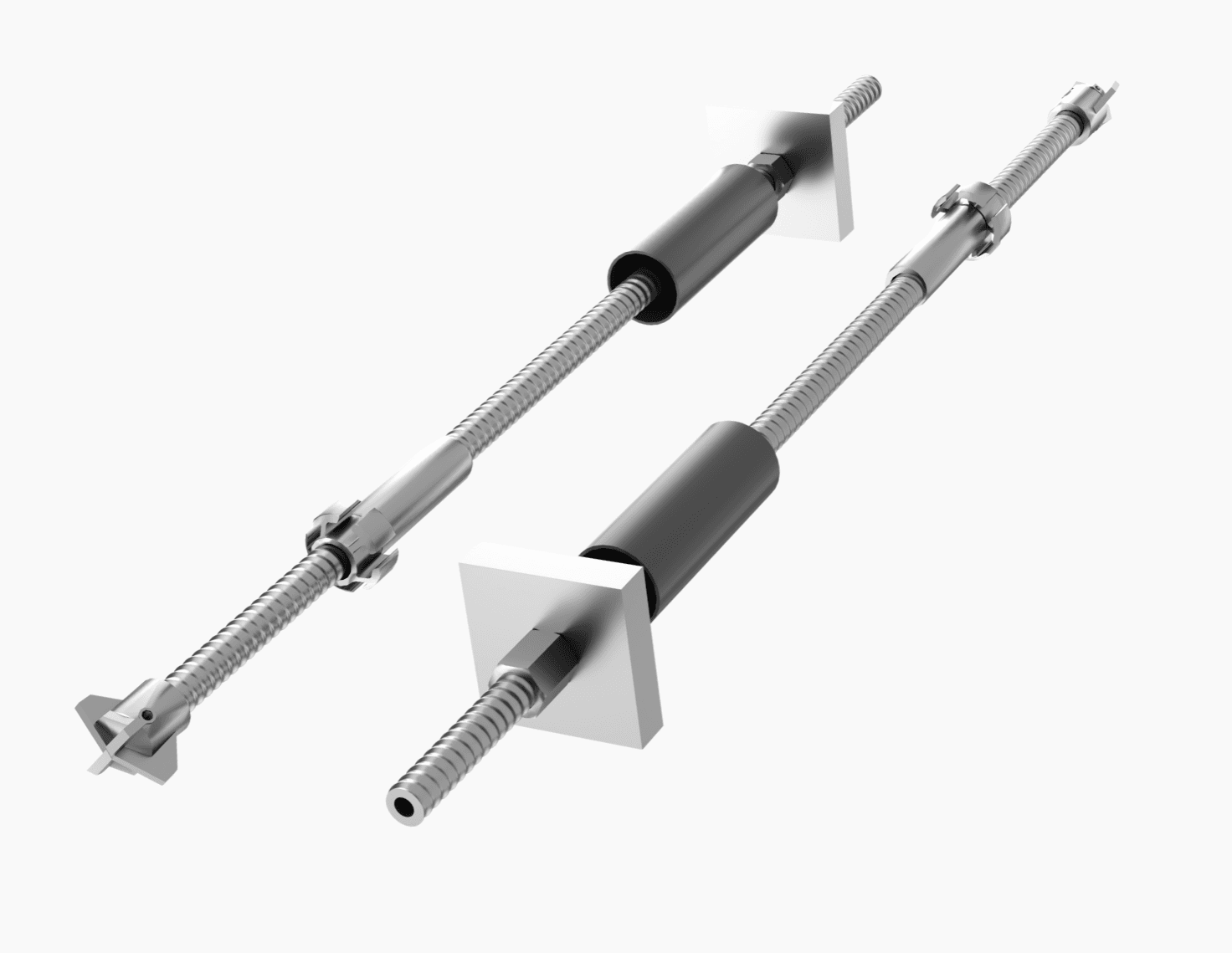

DYWIDAG’s DYWI® Drill Hollow Bar Micropile combines drilling, pressure‑grouting, and reinforcement in a single efficient operation, making it ideal for restricted-access sites, tight urban environments, unstable ground, or for projects where speed is critical.

This self-drilling micropile system is designed to support structures by transferring loads to deeper, more stable soil or rock. Whether you're underpinning an existing foundation, constructing a bridge abutment, or building in urban environments, DYWI® Drill provides reliable, high-capacity load transfer without the need for casing or pre-drilling.

Key features

Single pass installation

DYWI® Drill micropiles are installed using a single operation that combines drilling, grouting, and reinforcement. This reduces equipment needs, speeds up timelines, and eliminates the need for casing — even in collapsing ground conditions.

Performs in poor ground conditions

From loose fill to collapsing soils, the self-drilling design enables fast penetration and immediate support. The sacrificial drill bit and pressure-grouted bar ensure a strong bond where conventional piles can’t be used.

Ideal for restricted access sites

With compact rig compatibility, modular bar lengths, and a lightweight design, the system can be installed in basements, tunnels, urban infill locations, or beneath existing structures — wherever space is limited or headroom is tight.

High load-bearing capacity

Designed for tension, compression, and combined loading, the system can handle substantial structural demands. It's suitable for new construction or retrofitting foundations that require reliable deep-ground load transfer.

Construction site service and equipment rental

DYWIDAG supports your projects not only with reliable products, but also with a full range of on-site services and rental options to ensure smooth execution and dependable results:

- Pile testing - Comprehensive verification of soil nail performance to ensure safety and compliance with project requirements.

- Static load testing - Accurate assessment of load-bearing capacity for anchors and nails, giving confidence in long-term stability.

- On-site training or assistance - Expert guidance and practica...

DYWI® Drill Hollow Bar applications

Foundations and Underpinning

Enhances load-bearing capacity and provides additional support for new or existing foundations, particularly in weak or variable soils.

Micropiling

Forms small-diameter piles ideal for confined spaces, low headroom, or where minimal vibration and ground disturbance are critical.

Temporary or Permanent Retaining Structures

Offers structural reinforcement for both short-term excavation walls and long-term retaining solutions in infrastructure or building projects.

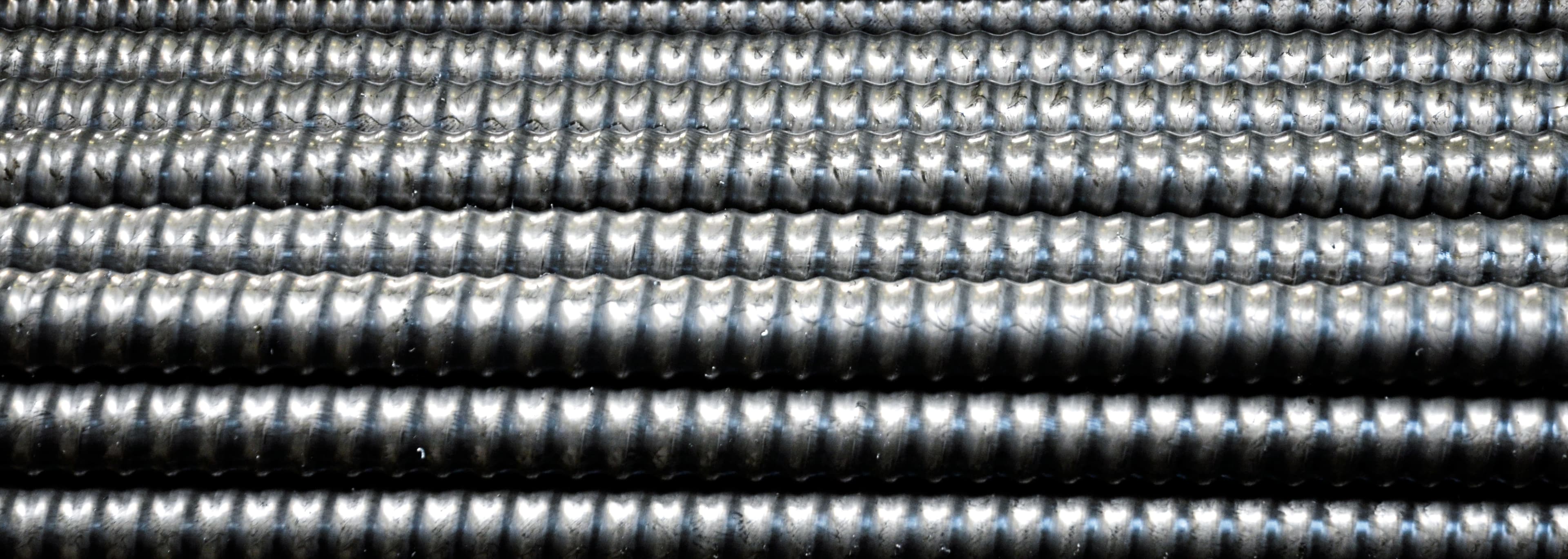

Manufactured to the highest standards

The DYWI® Drill hollow bar is a fully threaded, self-drilling solution for applications in civil engineering, including soil nailing, slope stabilization, micropiles, and rock anchoring. The design allows simultaneous drilling and grouting, eliminating the need for casing in weak or brittle soils - streamlining installation while meeting industry safety and quality standards.

Manufactured to the highest standards and compliant with regulations across the globe, DYWI® Drill Hollow Bar ensures rel...

Corrosion protection options

DYWI® Drill Hollow Bars are designed to perform in a wide range of environmental conditions—from dry inland soils to aggressive marine or chemically contaminated ground. To support both temporary and permanent applications, we offer flexible corrosion protection solutions tailored to project needs and service life expectations.

01 Grout Encapsulation - In many cases, DYWI® Drill Hollow Bars are installed with pressure-injected grout, creating an additional protective barrier that enhances durabil...

Related Accessories

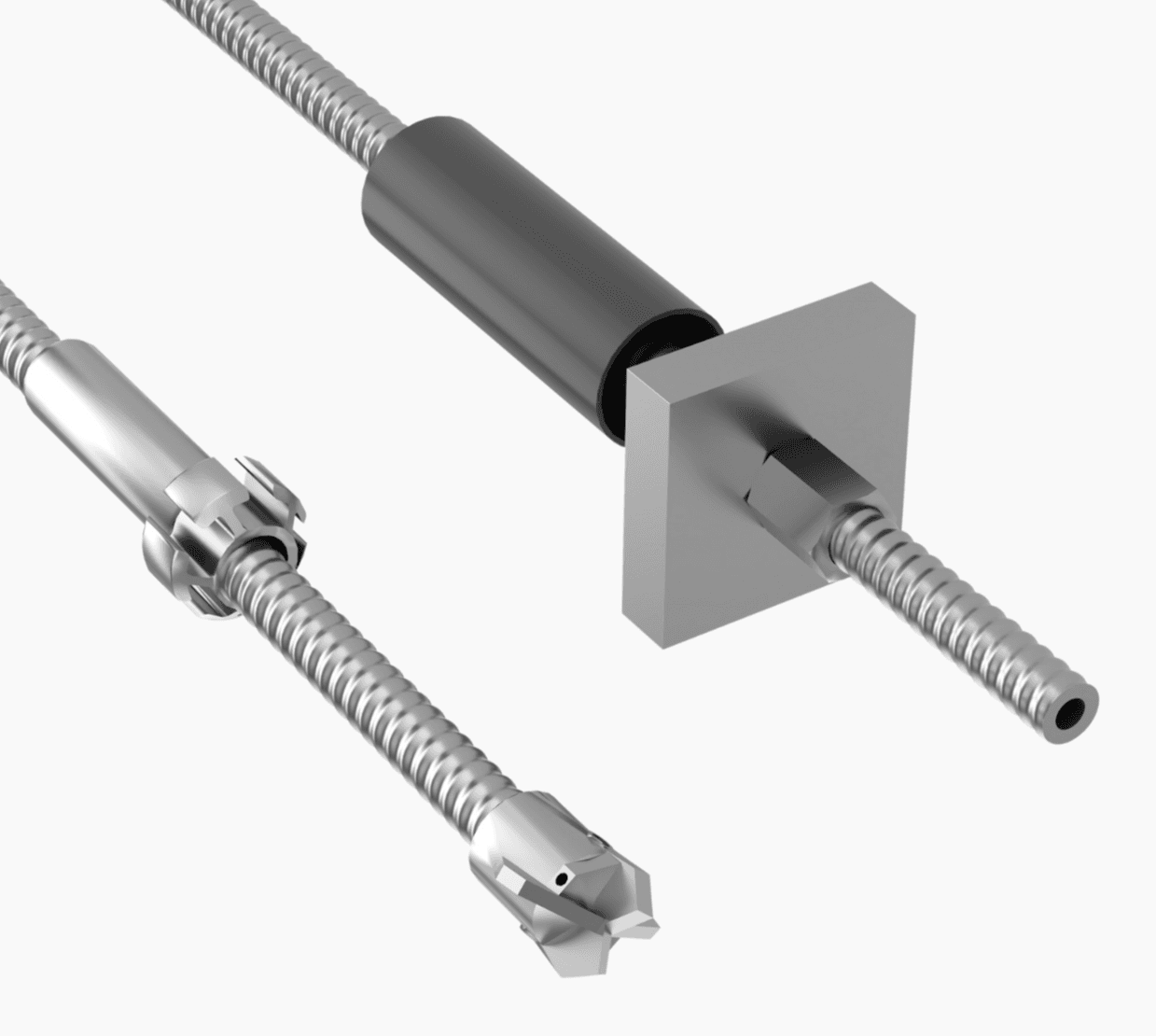

To support a wide range of geotechnical applications, the DYWI® Drill Hollow Bar system is available with a comprehensive range of precision-engineered accessories. Each component is designed to ensure safe, efficient installation and performance.

Core Accessories

01 Plates: Available in various shapes and sizes, plates distribute loads evenly to the surface and ensure secure anchorage.

02 Nuts : Used to tension the hollow bar and lock it in place. Options include hex nuts, spherical nuts, and coup...

Micropiles technical specifications 2

Positioning and Spacing

05 Centralizers: Maintain the correct positioning of the bar within the borehole, optimizing grout coverage and structural integrity.

Drilling Tools & Interfaces

06 Drill Bits: Available in multiple shapes and hardness levels to suit different ground conditions—from soft soils to hard rock.

07 Drill Bit Adapters: Connect the drill bit securely to the bar and transfer torque during drilling.

08 Shank Adapters: Interface between drilling equipment and the hollow bar system for s...

Related products

Sistema de microestacas Threadbar da DYWIDAG

O elemento de fundação ideal: econômico, compacto e resistente.

Sistema multibarras DYWIDAG

O elemento de fundação ideal para cargas mais altas.

DYWIDAG Auger Cast Pile

Solução econômica e moldada in-situ para cargas laterais mais altas.

DYWI® Drill Hollow Bar Soil Nail

Sistema autoperfurante para solo solto, sem necessidade de revestimento.

DYWIDAG GEWI® Threadbar Soil Nail

Rápido e econômico para aplicações temporárias e permanentes.

Parafuso de rocha com barra oca de perfuração DYWI

Incluindo opções de autoperfuração para solos problemáticos e onde a velocidade e a eficiência são fundamentais.

Parafuso de rocha expansível DYWIDAG

Estabilização instantânea sem rejunte.

Parafuso de rocha DYWIDAG GFRP

Parafusos de rocha cortáveis para uso em áreas urbanas, onde pode ser necessária uma escavação futura ou onde as condições ambientais favorecem um parafuso de polímero.

Sistema de parafusos para rocha Threadbar da DYWIDAG

Transferência de carga eficiente com várias opções.

Parafuso da rocha do estabilizador de fricção

Instalação rápida e fácil para suporte imediato.

Parafuso combinado DYWIDAG

Proteção superior para aplicações de longa duração.

Parafuso do cabo DYWIDAG

Sistema de reforço flexível com opção de pós-tensionamento.